To correct the moving speed of the ceramic tile in the kiln to avoid the breakage and prevent the

ceramic tile from hitting the kiln wall.

To ensure the flatness of the ceramic tile.

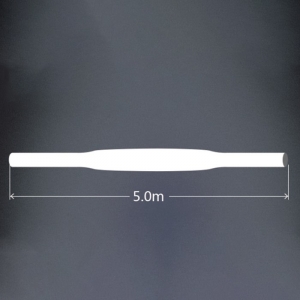

To adjust the moving direction of the ceramic tile by increasing the radian of roller in different

position of roller as per customer's requirement.

OK 818 CHEMICAL & PHYSICAL CHARACTERISTICS

|

ITEMS

| OK818 (RECTIFYING ROLLER) |

| MARKING COLOR | RED

|

| MAX. SERVICE TEMPERATURE | 1350℃ |

| REFRACTORY DEGREE | 1800℃ |

| RATE OF WATER ABSORPTION | 4.0~6.0% |

| ANTI-BENDING STRENGTH | 65~75MPa |

| THERMAL SHOCK RESISTANCE | ★★★★ |

| Al2O3 CONTENT | 76~78% |

| ZrO2 CONTENT | 5.0~8.0% |

| SiO2 CONTENT | 16-18 |

| METAL SI CONTENT | 0 |

| STANDARD DIMENSIONS |

| DIAMETERS (mm) | LENGTH (mm) | DIAMETERS (mm) | LENGTH (mm) |

| 65~80 | 3000 ~ 5300 | 40 | 2000 ~ 3500 |

| 60 | 2700 ~ 5000 | 36 | 2000 ~ 3300 |

| 55 | 2700 ~ 5000 | 35 | 2000 ~ 3200 |

| 52 | 2400 ~ 5000 | 33.7 | 1800 ~ 3100 |

| 50 | 2400 ~ 4600 | 32 | 1800 ~ 3100 |

| 45 | 2200 ~ 3800 | 20-31 | 1600 ~ 3100 |

| 42 | 2200 ~ 3800 | 12-19 | 1200 ~ 2800 |